![]()

How the new coins are made

The new coins are being made for the Reserve Bank of New Zealand at the Royal Canadian Mint in Canada. The coins are made using the following production process.

| The rolls of steel arrive in the factory. | The steel is fed onto the ‘blank’ coin making machine. |

| The machine cuts out ‘blanks’ for the coins. Each blank will become a 20 cent coin. |

| The blanks are passed through vats filled with a chemical solution. An electric current is applied and the copper and nickel metals dissolved in the chemical solution are transferred to the blanks. | All the completed blanks are computer checked for accuracy. |

![]()

| A random sample of the coins is checked for accuracy. The coins are cut through and examined under a microscope. The amount of copper and nickel must be within agreed tolerance levels. |

![]()

| A die is made with the image of the 20 cent coins. | It has the seven ‘spanish flower’ indentations. |

![]()

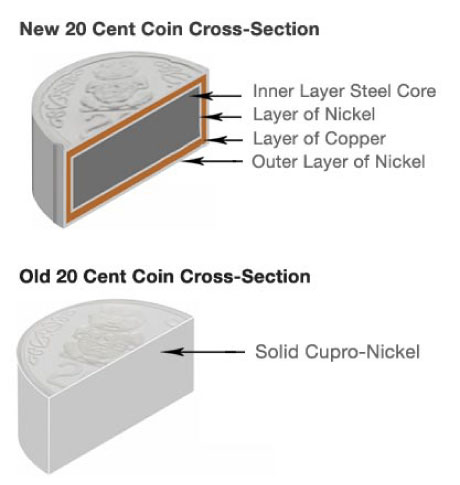

| The die is placed on the machine and the coins are ‘stamped’ with the images. | The 20 cent coin now has a plated steel core covered with a layer of nickel, then a layer of copper and a layer of nickel. |

![]()

| All the coins have their ‘electromagnetic signature’ checked to make sure they are within agreed tolerance limits and will be able to be read by New Zealand coin vending machines. | A machine stacks the coins in rolls. There are twenty five 20 cent coins in each roll. |

![]()

| People stack the rolls into boxes. | The boxes are stacked onto pallets for shipping to New Zealand. |

![]()

| The Reserve Bank stores the coins and releases them to banks as they require them. |

|

![]()